Press release

Seamless production processes – OneVision Software at Labelexpo Americas 2024

With OneVision's flexible Label Automation Suite, digital label printers can reduce manual file preparation time and unlock the full potential of high-speed presses and finishing equipment. OneVision’s solutions for production automation can be seen at Labelexpo Americas in Chicago from 10–12 September.

Woburn/Chicago. More than a third of all label printing is already fully digital or hybrid, and the trend is growing. However, incoming jobs often get bogged down in the file preparation stage, creating unnecessary interruptions in the workflow. To maximize production efficiency and save valuable resources, automation is a real game changer. Software manufacturer OneVision supports printing companies worldwide on their journey to automation.

At this year's Labelexpo Americas, visitors to OneVision's booth 5802 can not only experience the possibilities of process automation, but also learn more about how end-to-end workflow automation can be achieved with the upcoming LabelStream LS2000 inkjet label press from Canon U.S.A., Inc.

Competitive advantage through automation

“To produce labels with profitable margins, especially in the digital short run sector, any disruption in the workflow must be minimized. In label automation projects we are supporting worldwide, we often see that the presses cannot exploit their full throughput power due to bottlenecks in the file prep,” explains Hans Stoeger, Senior Director of Research & Development at OneVision Software. “Yet there are great solutions for automation available. Most file preparation tasks can run within seconds without any manual effort, intelligent grouping of artworks for print form creation enables significant savings in terms of material,” he adds.

Label printing software for automated production

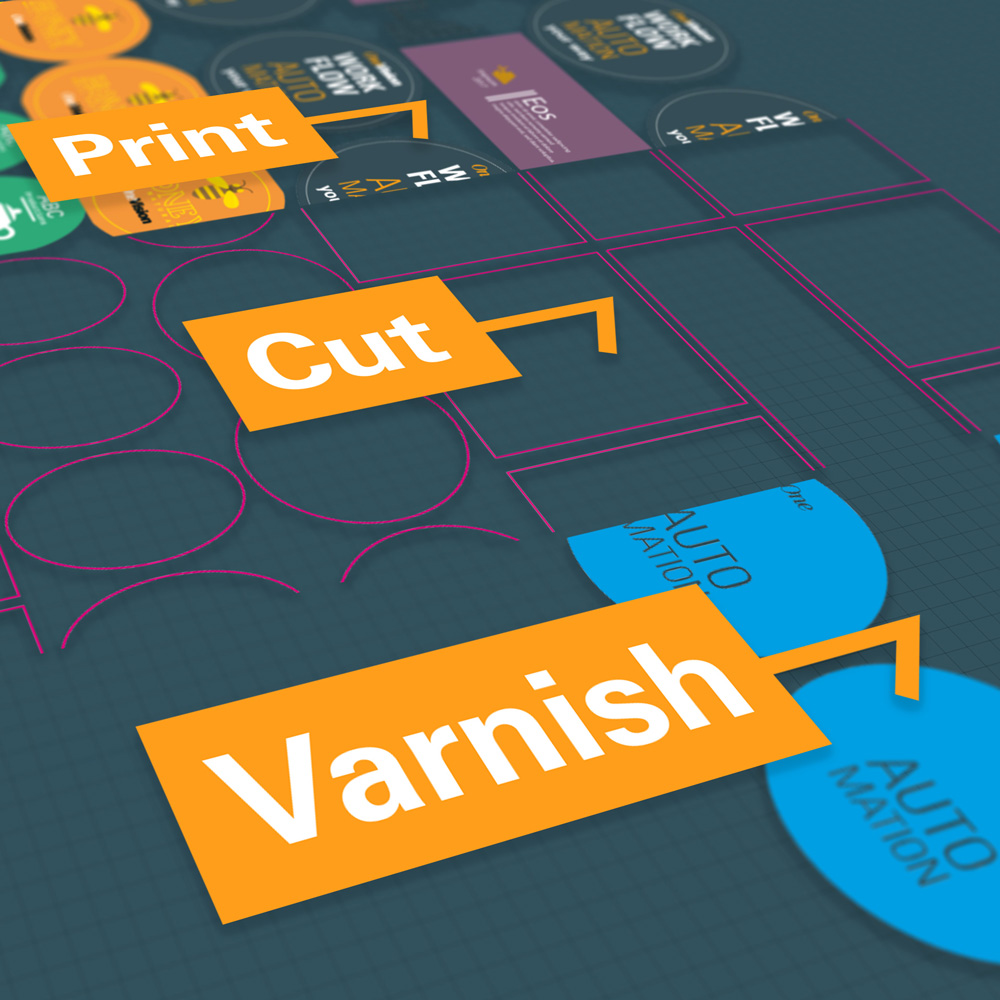

OneVision’s Label Automation Suite combines production planning with print file optimization. As flexible middleware, the software sits between job entry and output to press and finishing equipment, routing and preparing files automatically for production. All production steps are transparently mapped in the software as a 'digital job bag', enabling smooth automated label printing without wasting time. Intelligent print form creation allows users to combine different short run jobs and ensures maximum efficiency. Print files can be collected by process, substrate or other criteria, or even shared across jobs.

End-to-end workflow for heterogeneous production sites

OneVision software also enables seamless integration with existing system environments. Structured data exchange makes it easy to integrate the software into a printer's system landscape. Front-end integrations with web shop, MIS, ERP and back-end integrations with DFE, RIP, presses and finishing equipment (laser cutters, die cutters, embellishment devices, etc.) ensure on-demand connectivity.

“We are excited to preview the capabilities of the upcoming LabelStream LS2000 inkjet press that can help meet the ever-changing demands for digital, high-quality label converting,” says Shinichi “Sam” Yoshida, executive vice president and general manager, Canon U.S.A., Inc. “We look forward to Labelexpo Americas and demonstrating how our products can contribute towards efficient and versatile label production.”

OneVision will be represented with its own booth at Labelexpo Americas, booth 5802.

You are welcome to download the attached information material for your media activities.

Always up to date

For more news about OneVision and the latest trends in printing, please visit our NewsRoom.