Print 4.0

with process automation

Goodbye analog processes – sustainably increasing efficiency with process automation

Do you think your print jobs are too individual to be automated?

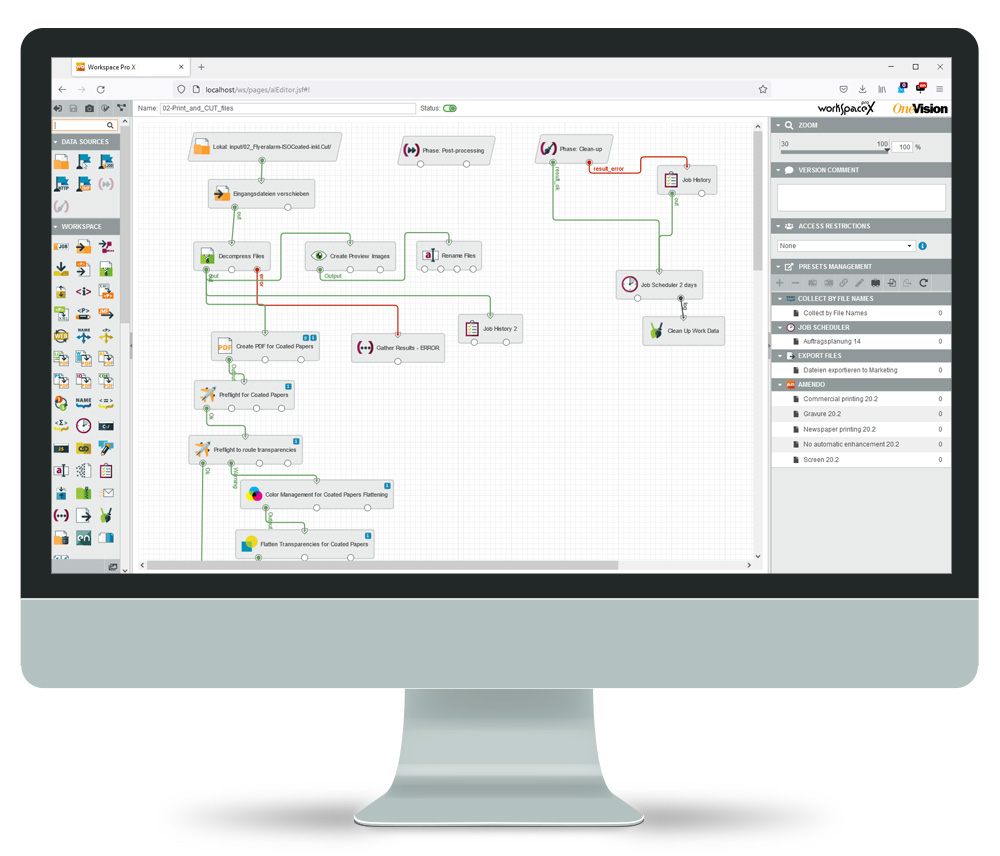

The more automated a print production is, the more efficiently it runs. After all, process automation ensures shorter throughput times and therefore lower costs. Why then, is the barrier to taking the step into automation and digitization still so great for many print service providers? One of the reasons given is flexibility. OneVision's software solutions are built in such a modular and flexible way that automation and flexibility do not contradict each other. Through an easy-to-use and highly flexible workflow management system, print service providers can digitalize their processes with a PDF metadata based workflow. Automation can be introduced fully or step by step as partial automation. For an efficient worfklow – even if each print job is different and non-recurring.

The benefits with automated workflows from OneVision

Process automation for your decisive competitive advantage:

- Time and cost savings through automated job processing

- Highest quality through the reduction of manual interventions

- Greater transparency for all employees involved thanks to digital order bag

- Detailed reporting to identify production peaks and possible bottlenecks at an early stage

- Potential for business growth through greater efficiency

Automate manual processes

If you are asked how manual processes in print production can be digitized and automated, the answer is as simple as it is comprehensive: With the right framework – the workflow management system - and the right set of tools, any workflow can be automated.

To begin with, your customer places an order with you, via your web store, by e-mail, or even by phone. A job ticket with the corresponding product properties and order information is created: Which product is to be produced (business cards, wallpapers, mega posters, labels, photo book...)? What is the print run, what is the format? The parameters in the job ticket are derived from the preconfigured products: the format, the bleed, information on color, the print date and much more. Working with this information - so-called properties – is essential for consistent and meaningful process automation of a print service provider’s workflow. But there is no magic in this, this PDF metadata is data that every job has always needed and that is available.

OneVision software solutions reliably process this information, enabling print service providers to realize Print 4.0. Sometimes it doesn't even have to be full automation. Even partial optimization creates efficiency and savings. The released capacities can be used for additional jobs and new services. Ultimately, this means that you optimize your company.

In the video you can see how analog processes are automated. The decisive factor here is the targeted use of job information: Color, size, format, substrate, date, number of pieces, number of pages, delivery date...This information is usually available in XML format and is the key to controlling print production – digital job pocket included!

Prepared for the future with Print 4.0

If you still don't trust automation 100%, you can of course insert checkpoints for visual inspection at almost any point. No matter what print product has been ordered, and what file you have received from your customer, our automation software ensures that your files are prepared for a smooth production process; automated and tailored to your needs – 24 hours a day, 7 days a week.